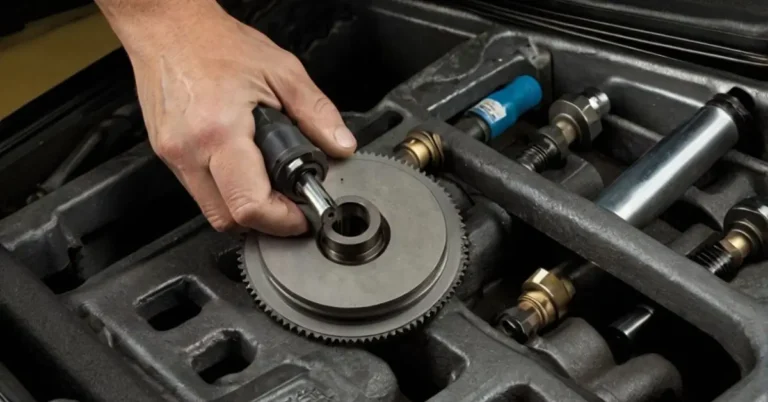

A clutch drive tool is a specialized instrument designed to assist with the maintenance, repair, and installation of clutch systems in vehicles, machinery, and other equipment. These tools are integral to ensuring that the clutch operates smoothly, extends its lifespan, and remains in optimal condition. For both professionals and DIY enthusiasts, clutch drive tools simplify tasks that could otherwise be labor-intensive and error-prone.

In this article, we’ll delve into the various types of clutch drive tools, their applications, benefits, and a comparison of popular options. By the end, you’ll have a thorough understanding of why these tools are essential for anyone working on clutch systems.

Types of Clutch Drive Tools

Clutch drive tools come in various types, each catering to specific tasks within clutch maintenance and repair. Below are some of the most commonly used types:

- Clutch Holding Tools

These tools secure the drive clutch in place, preventing it from rotating during installation or removal. They ensure that torque is applied correctly without causing damage to the clutch or surrounding components. - Clutch Pullers

Designed to remove the drive clutch from the engine shaft, clutch pullers are made from durable materials that withstand high stress. Their precision design ensures that the clutch is removed safely without damaging the shaft or clutch housing. - Pulley Opening Tools

Pulley opening tools allow for easy access to the drive pulley, making it simpler to replace belts or inspect internal components. These tools are particularly useful for powersports vehicles like ATVs and snowmobiles, where belt-driven systems are common. - Alignment Tools

Alignment tools help in positioning the clutch correctly during installation. Proper alignment is crucial to avoid excessive wear and ensure smooth operation of the clutch system. - Specialized Wrenches and Sockets

Some clutch systems require unique tools like custom wrenches or sockets for removing and tightening specific bolts and components.

How Clutch Drive Tools Work

Clutch drive tools are engineered to make complex tasks manageable. For instance:

- A clutch holding tool clamps onto the clutch securely, allowing you to loosen or tighten bolts without the clutch spinning. This eliminates the need for makeshift solutions that could lead to damage.

- A clutch puller threads into the clutch and uses mechanical leverage to pull the clutch off the engine shaft with minimal effort. Without this tool, removing the clutch could require excessive force, risking damage to both the clutch and the engine.

- A pulley opening tool applies pressure to the drive pulley, separating its halves for easy belt removal or inspection. This process is crucial for maintaining belt-driven systems.

By using the right tools, you ensure that clutch maintenance is performed safely and efficiently.

Applications of Clutch Drive Tools

Clutch drive tools have widespread applications across various industries and vehicles. Some of their primary uses include:

- Automotive Repair

In cars and trucks, clutch systems are critical for transferring power from the engine to the transmission. Clutch drive tools simplify the installation, removal, and adjustment of clutch components, ensuring smooth operation and reducing the risk of costly repairs. - Powersports Vehicles

ATVs, snowmobiles, and motorcycles often rely on belt-driven clutch systems. Specialized clutch tools are necessary for maintaining these systems, as they experience high wear and tear due to demanding conditions. - Industrial Machinery

In heavy machinery, clutches play a vital role in power transmission. Clutch drive tools enable routine maintenance, minimizing downtime and ensuring the machinery operates at peak performance. - DIY Repairs

For enthusiasts who prefer working on their vehicles or machinery at home, clutch drive tools make complex repairs achievable without professional assistance.

Benefits of Clutch Drive Tools

Using clutch drive tools offers numerous benefits, making them indispensable for professionals and hobbyists alike:

- Prevents Damage

The precision design of these tools ensures that clutch components are not damaged during maintenance. For instance, using a clutch puller prevents the excessive force that could damage the engine shaft. - Enhances Safety

Proper tools reduce the risk of injury during maintenance. They allow you to handle high-tension components like clutches and pulleys safely. - Saves Time and Effort

These tools streamline complex tasks, enabling faster and more efficient repairs. What might take hours with makeshift tools can often be accomplished in minutes. - Improves Longevity

Regular maintenance using the correct tools extends the lifespan of clutch components, reducing the need for frequent replacements. - Ensures Precision

Clutch systems require accurate torque application and alignment. Clutch drive tools provide the precision necessary for optimal performance.

Comparison of Clutch Drive Tools

Here’s a comparison of popular clutch drive tools based on their function, compatibility, and price range:

| Tool Type | Function | Compatibility | Price Range |

|---|---|---|---|

| Clutch Holding Tool | Secures clutch during maintenance | Cars, ATVs, Snowmobiles | $30–$70 |

| Clutch Puller | Removes clutch from engine shaft | Powersports and automotive | $20–$50 |

| Pulley Opening Tool | Opens drive pulley for belt work | Belt-driven systems | $40–$60 |

| Alignment Tool | Aligns clutch during installation | General automotive and powersports | $15–$40 |

| Specialized Sockets/Wrenches | Tightens or loosens specific bolts | Machinery and vehicles | $10–$30 |

Note: Prices vary based on brand and build quality.

Maintenance Tips for Clutch Drive Tools

To ensure that your clutch drive tools remain effective and durable, follow these maintenance tips:

- Clean After Use

Remove grease, dirt, and debris from the tools after each use. This prevents corrosion and ensures smooth operation. - Store Properly

Keep the tools in a dry, organized toolbox to avoid moisture exposure, which can lead to rust. - Inspect Regularly

Check for signs of wear, such as cracks or deformities. Replace any damaged tools promptly to avoid accidents or subpar performance. - Lubricate Moving Parts

For tools with moving components, apply a suitable lubricant to maintain their functionality. - Follow Manufacturer Instructions

Always use the tools as intended and adhere to any guidelines provided by the manufacturer.

Tips for Choosing the Right Clutch Drive Tool

Selecting the appropriate clutch drive tool depends on several factors:

- Vehicle or Machinery Type

Ensure the tool is compatible with your specific clutch system. Check for details about supported models or types. - Material Quality

Opt for tools made from durable materials such as hardened steel or forged aluminum. High-quality materials ensure longevity and reliability. - Ease of Use

Look for ergonomic designs that make the tool comfortable to handle during extended use. - Price and Warranty

While cost is a factor, prioritize quality over the lowest price. A tool with a warranty often reflects the manufacturer’s confidence in its durability.

Conclusion

A clutch drive tool is an essential companion for anyone involved in clutch maintenance and repair. Whether you’re a professional mechanic or a DIY enthusiast, these tools simplify complex tasks, enhance safety, and ensure the longevity of clutch components. By investing in the right tools and maintaining them properly, you can save time, reduce costs, and achieve professional-level results.

Whether you’re working on a car, an ATV, or heavy machinery, the right clutch drive tool will make all the difference. So, the next time you face a clutch-related task, ensure you have the appropriate tools to get the job done efficiently and effectively.