The dairy business must maintain product freshness and quality while fulfilling consumer demands for convenience and sustainability. Dairy products, one of the most perishable food groups, require innovative packaging to assure safety, shelf life, and taste and texture. Aluminum foil from China Aluminum Foil manufacturers, with its superior barrier characteristics and adaptability, has revolutionized dairy product packaging. Aluminum foil transforms dairy packaging, improving shelf life, waste reduction, and consumer happiness.

The Unique Dairy Product Packaging Challenges

Due to their high moisture content, temperature sensitivity, and light and oxygen exposure, dairy products like milk, cheese, yogurt, butter, and cream deteriorate easily. These variables cause microbial growth, oxidative deterioration, and taste and nutritional loss. Effective packaging helps mitigate these issues and ensure dairy product quality from manufacturing to consumption.

Plastics and paper-based packaging typically fail to safeguard dairy products. This gap has led to the use of aluminum foil, which has better barrier and functional properties.

Aluminum Foil Revolutionizes Dairy Packaging

Aluminum foil, a thin, flexible sheet of aluminum with amazing characteristics, is great for packaging. It is unique in its capacity to block light, oxygen, moisture, and pollutants. Aluminum foil is typically laminated or mixed with other materials in dairy packaging to improve functionality and meet product needs.

Excellent Barrier Properties

Aluminum foil is ideal for dairy packaging due to its barrier qualities. It prevents light and oxygen, which degrade dairy products. Photooxidation, especially from UV radiation, causes off-flavors and discoloration. Oxygen ingress promotes aerobic bacteria growth and oxidative rancidity, speeding deterioration.

Aluminum foil preserves dairy products’ freshness, taste, and nutritional content by blocking light and oxygen. Milk and cheese must maintain their sensory and quality features, so this is vital.

Heat Sealability and Temperature Resistance

Aluminum foil is versatile for dairy packaging because of its temperature resilience. It can endure high and low temperatures, making it useful in pasteurization and freezing. To safeguard the product during sterilization, foil-lined boxes and pouches can withstand heat.

Aluminum foil’s heat sealability creates airtight seals, enhancing packing integrity. This keeps dairy products fresh and safe by preventing leakage, contamination, and spoiling.

Flexibility and adaptability

Aluminum foil from China Aluminum Foil suppliers flexibility allows it to be molded into several shapes and sizes for packaging. It can package dairy products in wraps, lids, pouches, and containers. Its interoperability with printing and embossing technologies allows for visually appealing and informational packaging that grabs customer attention.

Benefits of sustainability

The packaging sector is increasingly concerned about sustainability, and aluminum foil meets this need. Aluminum recycling uses less energy than initial production and is highly recyclable. Aluminum foil dairy packaging lowers waste and conserves resources. Its lightweight design reduces transportation emissions, boosting its sustainability.

Application of Aluminum Foil in Dairy Packaging

Aluminum foil is used in diverse ways to meet dairy product needs. Common uses include:

- Foil-lined cartons

Milk, cream, and flavored drinks are often packaged in foil-lined cartons. The aluminum layer blocks light and oxygen, while the paperboard offers strength. These cartons are perfect for distribution in areas with limited cold storage since they last long without refrigeration.

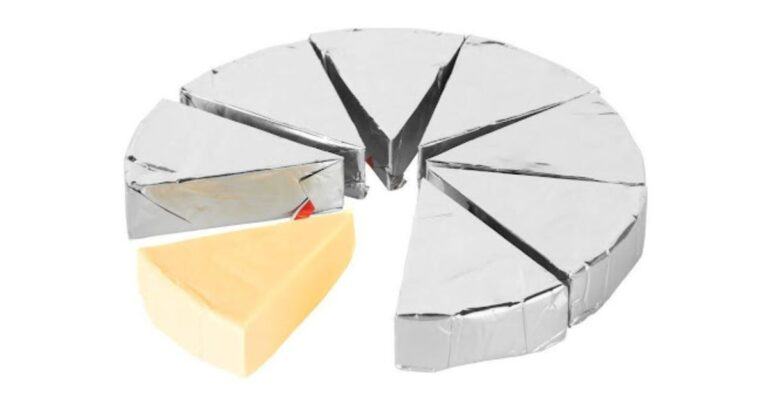

- Foil-wrapped cheese and butter

Butter and cheese are wrapped in aluminum foil to maintain flavor, aroma, and texture. The foil protects the product against moisture loss, smells, and contaminants and makes packing easier to handle and store.

- Yogurt Covers and Seals

Aluminum foil lids are common for yogurt cups and other dairy containers. Their superb sealing properties keep the product fresh and safe, and the foil lid is tamper-evident, boosting consumer trust.

- Flexible Pouches

Flexible pouches with aluminum foil layers are popular for cream, condensed milk, and dairy sauces. These lightweight, easy-to-open pouches have a long shelf life and are useful for customers and manufacturers.

- Frozen Dairy

Aluminum foil is ideal for packaging frozen dairy products like ice cream and yogurt because it can withstand freezing conditions. The product is protected from freezer burn and temperature variations during storage and shipment.

Aluminum Foil Packaging Improves Customer Satisfaction

Aluminum foil packaging improves consumer experience beyond product preservation. Modern consumers want simplicity, safety, and sustainability in packaging, which aluminum foil delivers.

Convenience and Function

User-friendly aluminum foil packaging allows easy opening, resealing, and disposal. Pull tabs and peel-off lids make items easier to obtain, while resealable pouches keep partially used products fresh.

Product Safety and Hygiene

Food safety depends on packaging, and aluminum foil protects against infection and tampering. The material’s impermeability keeps hazardous bacteria out, ensuring product hygiene and quality.

Visual Appeal and Branding

Elegant packaging influences customer purchases, and aluminum foil’s compatibility with sophisticated printing techniques allows for eye-catching patterns. With brilliant colors, elaborate designs, and embossed logos, aluminum foil packaging boosts brand awareness on store shelves.

Ecological Responsibility

Consumers care about sustainability and aluminum foil’s recyclability and resource efficiency appeal to them. Aluminum foil packaging can show dairy firms’ environmental awareness, boosting consumer loyalty.

Dairy Product Aluminum Foil Packaging Innovations

Technology keeps pushing aluminum foil packaging, creating new solutions for dairy industry difficulties and opportunities. Some important innovations are:

- Multi-Layer Laminates

Multi-layer laminates made from aluminum foil, plastic films, and paperboard work better. These laminates meet dairy products’ various needs with outstanding barrier protection, mechanical strength, and design flexibility.

- Smart Packaging

Aluminum foil packaging with smart technology can have freshness indicators, QR codes, and temperature sensors. These advances give consumers real-time product quality and storage information, boosting confidence and satisfaction.

- Lightweight Foil Structures

Thanks to manufacturing advances, thinner, lightweight aluminum foil structures that perform well and use less material have been developed. These structures achieve cost savings and environmental benefits without losing package effectiveness.

Conclusion

Aluminum foil from China Bopp film manufacturers has transformed dairy product packaging with its superior barrier, adaptability, and sustainability. Its ability to maintain freshness and quality while meeting consumer demands for convenience and environmental responsibility makes it essential in the dairy business. As technology advances, aluminum foil packaging will redefine dairy packaging by maximizing shelf life, reducing waste, and improving consumer pleasure.