Table of Contents

- Introduction to Air Casters

- Advantages of Air Casters in Material Handling

- Applications Across Industries

- Enhancing Safety and Ergonomics

- Protecting Factory Floors

- Integration with Modern Manufacturing

- Future Trends in Air Caster Technology

- Conclusion

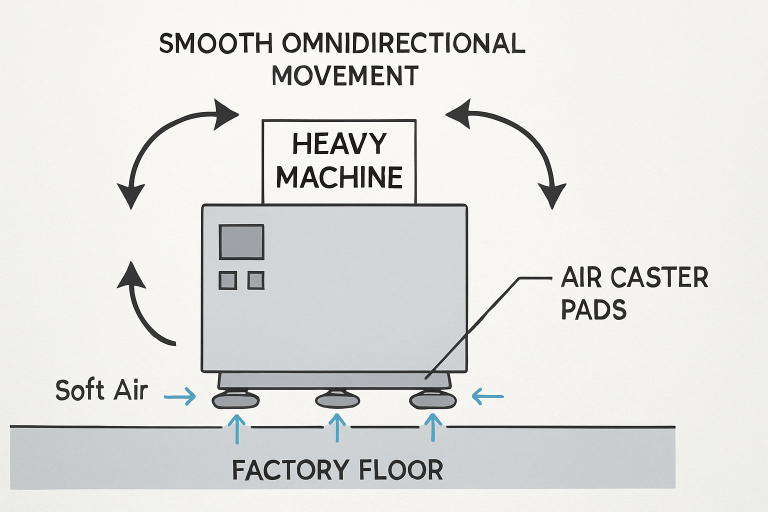

Industrial environments continue to push for safer, more efficient, and cost-effective solutions for moving heavy loads. Among the breakthroughs making this possible, air casters have emerged as a powerful alternative to traditional rollers and cranes. Using a thin cushion of compressed air, they allow the effortless movement of massive equipment, bringing flexibility and precision to facility operations. Compared with mechanical alternatives such as cranes or forklifts, air casters drastically reduce manual effort. This is especially relevant in today’s factories, where ergonomic design and operational efficiency go hand in hand with worker safety. For those seeking other heavy-duty load-handling solutions, shock absorbing suspension casters also offer specialized benefits for challenging applications.

The adoption of air caster systems is revolutionizing material handling by alleviating production bottlenecks and promoting flexible manufacturing. Their design allows for maneuverability of heavy machinery in confined spaces, reducing downtime and enhancing safety. Employed across various industries, air casters use compressed air to create a thin film that supports and moves heavy equipment with minimal friction, making them ideal for delicate surfaces. This technology, supported by advancements such as predictive maintenance, offers businesses the potential for safer, more efficient operations.

Advantages of Air Casters in Material Handling

Switching to air casters introduces several competitive advantages for warehouses and factories:

- Reduced Manual Effort: Air casters enable a small team or even a single operator to move equipment weighing thousands of pounds with minimal physical effort, improving efficiency and reducing the likelihood of workplace injuries.

- Full Range Movement: With 360-degree mobility, these casters excel in spaces where navigating corners and tight areas is crucial.

- Floor Preservation: The air cushion evenly distributes heavy loads, preventing gouges, cracks, and the need for frequent floor repairs.

- Adaptability: This technology can be applied to a wide variety of load shapes and sizes and is beneficial in clean manufacturing environments where contamination from wheels must be avoided.

Applications Across Industries

Air casters are making significant inroads into multiple sectors:

- Manufacturing: Facilities that build modular homes rely on air casters to smoothly transfer entire sections between workstations, helping keep assembly lines flowing and minimizing non-value-added labor.

- Aerospace: Aircraft factories use air casters to maneuver large, delicate components such as fuselage sections, reducing both damage risk and handling time.

- Energy Sector: In power facilities, maintenance or upgrades on turbines and similar equipment are quicker and safer thanks to air-caster platforms that gently glide even the bulkiest machinery into place.

Enhancing Safety and Ergonomics

Workplace injuries related to moving heavy objects are a persistent challenge in industrial settings. Air casters minimize this risk by enabling smooth, low-exertion motion and facilitating gradual, precise equipment movements. This drastically reduces the possibility of musculoskeletal disorders and supports broader safety initiatives. It also contributes to improved worker morale and supports legal compliance with standards such as those set by OSHA, keeping both employees and companies protected.

Protecting Factory Floors

Equipment such as forklifts, cranes, or traditional carts often leaves scuff marks, scratches, or even deep cracks in facility floors. Air casters virtually eliminate this concern, as their load is distributed over a large surface with a soft cushion of air. This characteristic helps organizations avoid the high cost of floor resurfacing, especially in areas such as cleanrooms, laboratories, or high-gloss epoxy-coated floors, where any damage risks operational compliance.

Integration with Modern Manufacturing

The adoption of air casters aligns perfectly with Industry 4.0 initiatives by allowing for rapid reconfiguration of production floors. Because equipment can be repositioned on demand, manufacturers can easily shift between product lines, test new layouts, or integrate new technologies without extensive downtime. Connected air-caster systems can also provide valuable operational data for process optimization and preventive maintenance scheduling, further boosting plant efficiency. This level of adaptability is critical as consumer demands shift and supply chains evolve.

Future Trends in Air Caster Technology

The future of air caster technology is being shaped by several major trends. As automation becomes more deeply integrated into plant operations, air casters are evolving with smarter controls, higher capacities, and digital connectivity. The focus on environmental responsibility is also driving the development of energy-efficient designs and recyclable materials. From fully automated guided vehicles using air-bearing platforms to AI-enabled movement control, these innovations are expected to further expand the use cases for air casters across sectors.

Conclusion

Air casters represent a transformative shift in industrial material handling, offering unparalleled flexibility, safety, and precision for moving heavy loads. Their impact is being felt across diverse industries as companies strive for more efficient, damage-free, and safe operations. As technological advancements continue to push boundaries, the role of air casters in shaping agile, sustainable, and smart factories will only strengthen, paving the way for a new era in industrial logistics and materials movement.