Key Takeaways

- Assessing project-specific water management requirements is critical for effective dewatering.

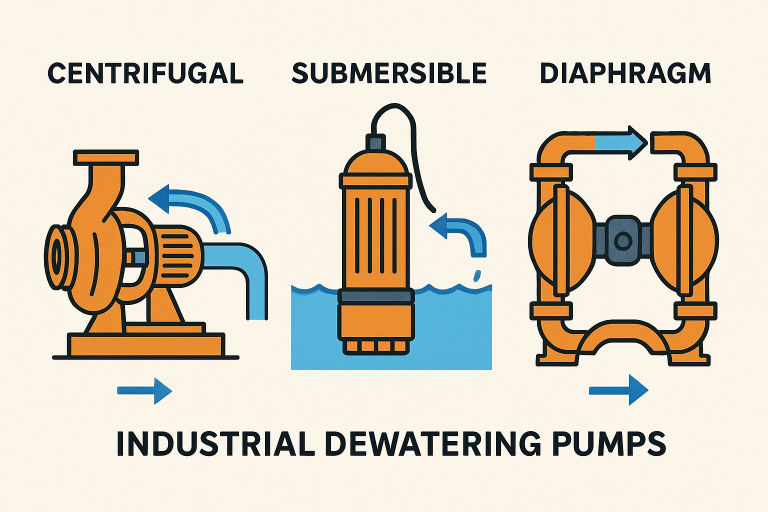

- Understanding the differences among centrifugal, submersible, and diaphragm pumps ensures correct equipment selection for specific environments and water types.

- Energy efficiency, equipment versatility, durability, and adherence to environmental standards impact both operational success and long-term costs.

- Factoring in the total cost of ownership and ongoing maintenance protects against unexpected expenses and project delays.

Understand Your Project Requirements

Industries ranging from construction and mining to chemical processing have unique water management challenges. The foundation of effective dewatering starts with a clear understanding of your project’s scope—evaluating the volume of water to be managed, identifying whether contaminants or solids are present, and determining the urgency or speed at which water must be removed.

Certain project sites—for example, construction zones with high groundwater infiltration—may demand highly specialized equipment such as robust industrial pumps or plate and frame rental systems to maximize efficiency. The right choice here ensures that your operation addresses immediate dewatering needs, complies with environmental guidelines, and minimizes overall operational disruption.

Environmental conditions also play a major role. Seasonal weather variations, soil composition, and water table fluctuations can all impact equipment requirements. Deep excavation or sites with significant particulates may require equipment built to handle mud, gravel, or silt without clogging or breakdowns. Consulting with a dewatering equipment professional can help match equipment specifications to your site’s geotechnical data.

Factoring in all these elements at the project’s outset is essential to safeguard productivity and regulatory compliance throughout operations.

Types of Dewatering Equipment

The variety of dewatering equipment on the market allows industry leaders to precisely align solutions with their application needs. However, not all equipment works efficiently across every scenario, and choosing the wrong tool can hinder project timelines and introduce additional costs.

- Centrifugal Pumps: These pumps are best for moving large volumes of relatively clean water and are favored in infrastructure projects and open mining sites. Their reliance on rotational energy makes them powerful yet susceptible to damage when solids or grit are present.

- Submersible Pumps: Engineered for water removal at depth and in challenging locations, submersible pumps can handle varied water consistencies, including those laden with sludge or particulates. They are sealed to operate underwater, reducing the risks of pump burnout common to surface-mounted alternatives.

- Diaphragm Pumps: Featuring a flexible diaphragm and check valves for debris-laden or abrasive fluids, diaphragm pumps excel in muddy, sandy, or highly variable conditions. Construction, tunneling, and environmental remediation projects often rely on these units for solid-laden site water.

Evaluate Energy Efficiency

Operational cost and environmental impact are increasingly intertwined concerns for industrial sites investing in new equipment. Modern dewatering pumps offer built-in technologies such as variable speed drives, smart sensors, and energy-saving hydraulics. Sourcing equipment with these features helps reduce a project’s carbon footprint and utility expenditure while aligning with global sustainability mandates.

Consider Equipment Versatility

Versatile dewatering equipment can adapt to fluctuating site conditions and a broad range of contaminants or solids, protecting your initial investment for the life of your facility or project. Many industrial sites now favor pumps with modular or adaptable components—such as interchangeable impellers or configurable drive systems—that allow upgrades or changes without full replacement. This modularity adds resilience to your water management system, allowing you to respond quickly to changing project demands or environmental factors.

Assess Maintenance and Durability

Routine maintenance and reliability are critical in industrial settings, where an unexpected equipment failure can lead to significant downtime and lost revenues. Dewatering pumps built from wear-resistant materials and designed for straightforward service minimize operational disruptions. Look for solutions that provide accessible parts, long-service intervals, and manufacturer support for repairs or routine maintenance, extending equipment life and reducing your total cost of ownership.

Analyze Total Cost of Ownership

The upfront price of dewatering equipment is only one part of the investment equation; long-term costs tied to energy use, routine service, and unplanned shutdowns can add up substantially over years of operation. Equipment that boasts high energy efficiency or minimal service requirements, such as low-speed motors or gravity-assisted drainage, often delivers substantial lifetime savings. Carefully review each product’s specifications and warranty coverage to ensure it meets your budget and operating demands over the long term.

Ensure Compliance with Environmental Regulations

Modern regulations governing water discharge, sediment removal, and site restoration are stringent, and non-compliance can mean fines or project delays. Selecting dewatering equipment that minimizes environmental disturbance helps protect natural resources while also streamlining permit acquisition. In projects with sensitive ecosystems nearby, innovative options like geotextile tubes provide powerful water filtration and sediment containment without heavy construction or repeated site entry, supporting compliance and corporate sustainability goals.

Final Thoughts

With industrial water management central to efficient, safe, and profitable project execution, selecting the right dewatering equipment is a high-impact decision. By systematically evaluating your site’s needs, available technologies, energy performance, adaptability, durability, and regulatory environment, you secure better long-term outcomes for your project and your business. Careful planning and informed equipment selection today can help avoid costly missteps, ensure regulatory compliance, and support your company’s sustainability initiatives well into the future.