Is it possible to reshape entire industries with one type of machine? Computer Numerical Control (CNC) technology is doing exactly that.

From automotive parts to aerospace components, CNC machines are changing the way products are made. They bring speed, accuracy, and consistency like never before.

This blog post explores how CNC technology is boosting precision, efficiency, and innovation across industries worldwide. By the end, you’ll understand why CNC is not just a tool but a true game-changer in manufacturing. Read on!

Precision Like Never Before

It is well known that computing numerical control (CNC) machines are very accurate. Every part comes from a digital design, so mistakes are less likely to happen.

It’s possible to make even the most complicated shapes right the first time. It is very important to have this level of accuracy in fields like medicine and aerospace, where even small mistakes can cost a lot of money. The use of CNC technology makes sure that every product is an exact copy of the design.

Speeding Up Production

It is no longer necessary for manufacturers to rely on manual labor to produce detailed parts. It is possible for CNC machines to operate without much supervision around the clock.

Not only are they quicker than conventional tools, but they also do not become fatigued or distracted. Customers will experience shorter wait times as a result of this, which leads to faster production times. The result is that businesses are able to more easily meet deadlines and maintain their competitive edge.

Lowering Costs Over Time

While the initial investment in CNC machines may be high, the long-term savings are well worth the investment. As a result of cutting only what is required from the raw materials, they generate less waste.

Due to the fact that they are automated, they also reduce the costs of labor. Machines are easy to maintain, and if they are cared for properly, they can last for many years. In the long run, manufacturers experience significant cost reductions and an increased return on investment.

Boosting Innovation in Design

CNC technology lets people be creative when they design products. Digital software makes it easy for designers to try out new ideas.

It’s now easy to make patterns and shapes that were too hard to make before. You don’t have to start from scratch to make changes to a product. This lets businesses come out with new and better products more often.

Improving Workplace Safety

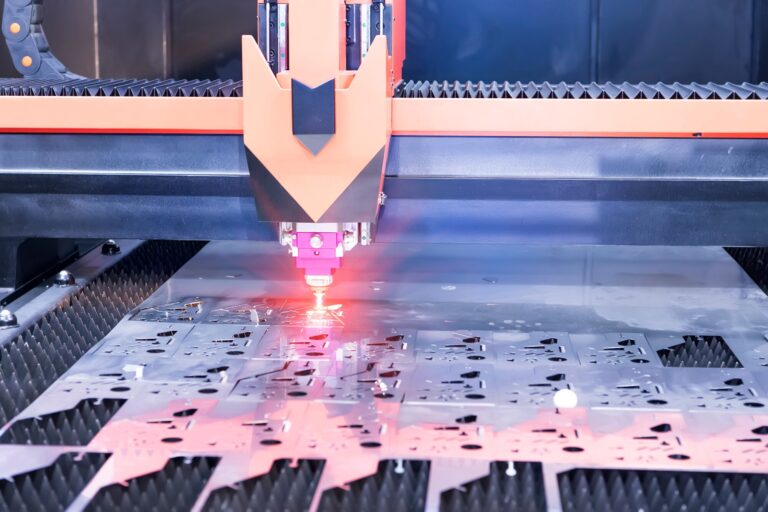

Manual cutting tools can be dangerous and require full attention. CNC machines work behind safety enclosures, keeping workers at a safe distance.

Operators can control machines from a computer without touching the moving parts. This reduces the risk of accidents and injuries. A safer workplace means happier employees and fewer insurance claims.

Serving Many Industries Worldwide

CNC machines are used in many types of businesses, big and small. From cars and planes to furniture and jewelry, they make all kinds of products.

A local CNC machine shop can create custom items for customers in different fields. This flexibility makes CNC technology useful in nearly every industry. As more companies adopt it, its impact keeps growing.

A New Era in Manufacturing

CNC technology is truly transforming the way products are designed and made. With better accuracy, lower costs, and faster production, it helps businesses grow and compete globally.

It also inspires new ideas, keeps workers safe, and serves many industries. This powerful tool is not just a trend- it’s shaping the future of manufacturing.

Did you like this guide? Great! Please browse our website for more!